VFD Training Course

Course Overview:

The VFD Training Course covers a wide range of topics to equip participants with the knowledge and practical skills necessary to effectively work with variable frequency drives. The course curriculum includes:

Introduction to Variable Frequency Drives: Participants will gain an understanding of the principles of operation and basic functions of variable frequency drives. Topics include motor control theory, frequency control, and VFD components.

VFD Selection and Sizing: This module covers the criteria for selecting and sizing VFDs based on motor specifications, load characteristics, and application requirements. Participants will learn how to calculate motor horsepower, voltage, and current ratings for optimal VFD selection.

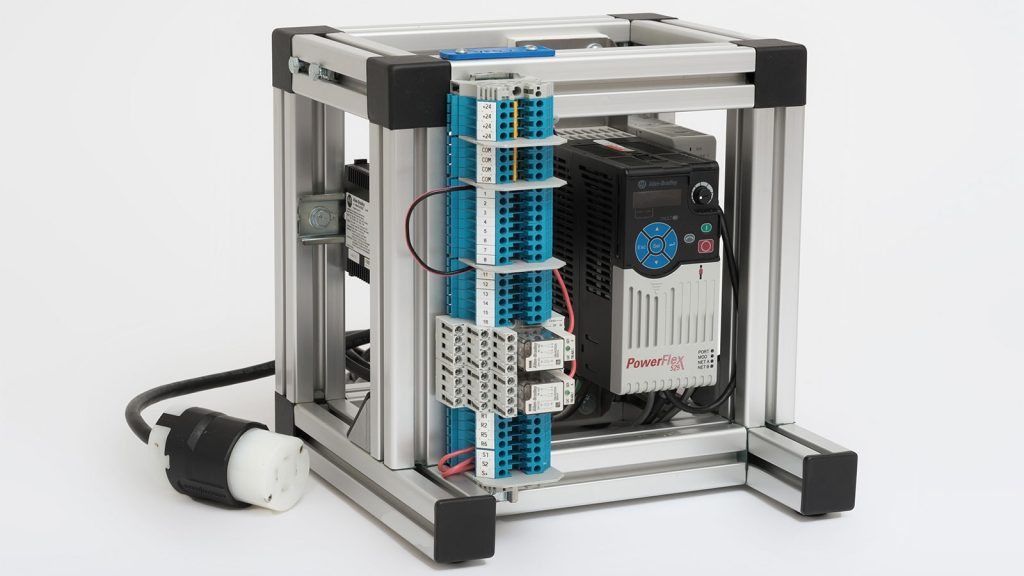

VFD Installation and Wiring: Participants will learn best practices for installing and wiring VFDs in industrial applications. Topics include electrical safety, grounding, motor connections, and cable sizing.

VFD Control Methods: Participants will explore different control methods used in VFDs, including scalar control (V/f control) and vector control (sensorless vector control and flux vector control). Emphasis is placed on understanding the advantages and limitations of each control method.

Energy Efficiency and Power Factor Correction: This module covers techniques for improving energy efficiency and power factor correction using VFDs. Participants will learn how VFDs can help reduce energy consumption, minimize motor wear, and

improve overall system performance.

VFD Troubleshooting and Maintenance: Participants will develop troubleshooting skills to diagnose and resolve common VFD-related issues. Topics include fault diagnostics, parameter adjustment, and preventive maintenance practices.

Course Format:

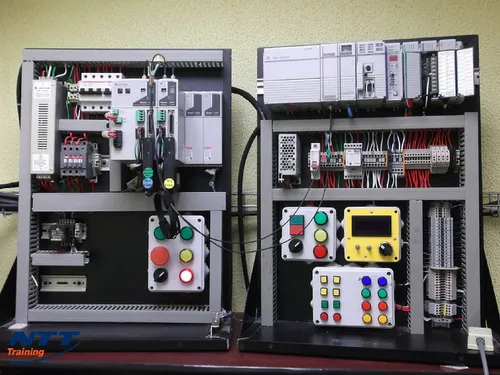

The VFD Training Course combines theoretical lectures with hands-on practical exercises using industry-standard VFD hardware and software platforms. Participants will have the opportunity to program, configure, and test VFDs in simulated industrial

environments.

Who Should Attend:

This course is suitable for engineers, technicians, and professionals involved in industrial automation, motor control, and energy management. It is also beneficial for students and graduates seeking to pursue a career in VFD applications and control.

Prerequisites:

Participants are expected to have a basic understanding of electrical engineering principles and familiarity with motor control systems. Prior experience with PLCs and industrial automation concepts is recommended but not required.

Certification:

Upon successful completion of the VFD Training Course, participants will receive a certificate of completion from Kushtia Industrial Automation, recognizing their proficiency in VFD operation, programming, and troubleshooting.

If the course duration is 3 months with a total of 36 classes, it suggests that classes would be held regularly, likely on a weekly basis, with each class lasting approximately 2 to 3 hours.

This setup allows for comprehensive coverage of course materials and concepts over the span of three months, ensuring that students have ample time to absorb information, participate in practical exercises, and engage with instructors.

During this period, students can expect a structured curriculum that progresses logically from foundational concepts to more advanced topics, with opportunities for hands-on practice and reinforcement of learning objectives. Additionally, assignments, projects, or assessments may be integrated throughout the course to evaluate student progress and understanding.

Overall, the 3-month duration with 36 classes provides a balanced and effective learning experience that prepares students for success in the field of industrial automation.