Advance PLC Training Course

Course Code: KIABA

The Advance PLC Training Course offered by Kushtia Industrial Automation is designed to provide participants with an in-depth understanding of advanced programmable logic controller (PLC) programming techniques and applications. This course is ideal for individuals seeking to enhance their expertise in industrial automation and control systems.

Course Overview:

The Advance PLC Training Course covers a wide range of topics to equip participants with the skills and knowledge necessary to tackle complex automation challenges effectively. The course curriculum includes:

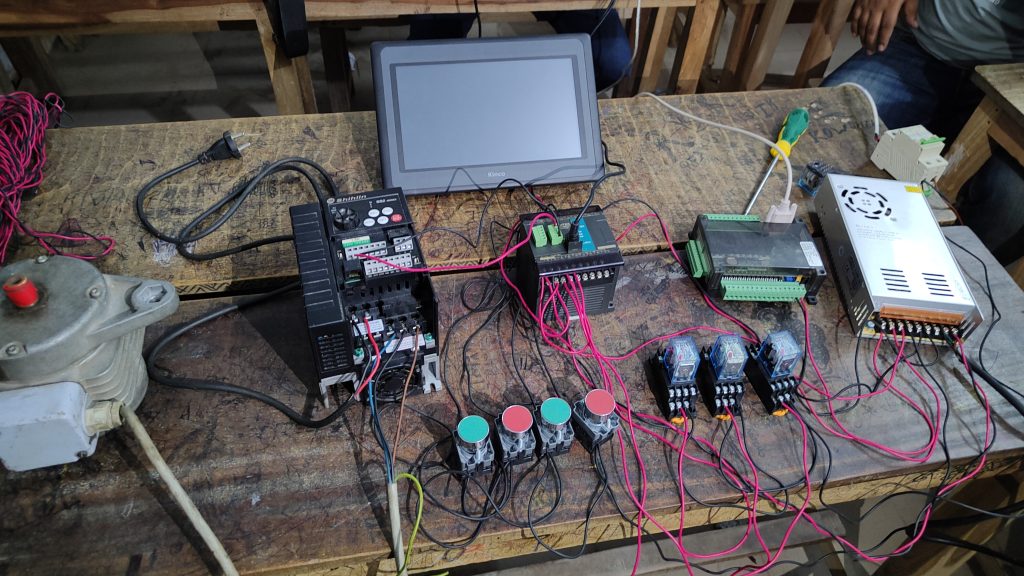

Advanced PLC Programming Techniques: Participants will learn advanced programming concepts, including ladder logic programming, function block diagrams (FBD), structured text (ST), and sequential function charts (SFC). Emphasis is placed on writing efficient and scalable PLC code for complex automation tasks.

Networking and Communication Protocols: Participants will explore PLC networking fundamentals and communication protocols commonly used in industrial automation systems. Topics include Ethernet/IP, Modbus TCP/IP, Profibus, and DeviceNet.

PLC Hardware Configuration: This module covers PLC hardware configuration and selection considerations, including processor types, input/output (I/O) modules, and communication modules. Participants will gain practical experience in configuring PLC hardware for specific automation requirements.

Advanced PLC Troubleshooting: Participants will develop advanced troubleshooting skills to diagnose and resolve complex PLC-related issues. Topics include troubleshooting ladder logic programs, analyzing system faults, and using diagnostic tools effectively

PLC Security and Safety: This module covers best practices for ensuring the security and safety of PLC systems. Participants will learn about access control, data integrity, and cybersecurity measures to protect PLCs from unauthorized access and cyber threats.

Course Format:

Who Should Attend:

This course is suitable for engineers, technicians, and professionals involved in industrial automation, control systems, and PLC programming. It is also beneficial for students and graduates seeking to pursue a career in industrial automation engineering.

Prerequisites:

Participants are expected to have a basic understanding of PLC programming concepts and industrial automation fundamentals. Familiarity with PLC hardware and software platforms is recommended but not required.

Certification:

Upon successful completion of the Advance PLC Training Course, participants will receive a certificate of completion from Kushtia Industrial Automation, recognizing their proficiency in advanced PLC programming and automation techniques.

If the course duration is 3 months with a total of 36 classes, it suggests that classes would be held regularly, likely on a weekly basis, with each class lasting approximately 2 to 3 hours.

This setup allows for comprehensive coverage of course materials and concepts over the span of three months, ensuring that students have ample time to absorb information, participate in practical exercises, and engage with instructors.

During this period, students can expect a structured curriculum that progresses logically from foundational concepts to more advanced topics, with opportunities for hands-on practice and reinforcement of learning objectives. Additionally, assignments, projects, or assessments may be integrated throughout the course to evaluate student progress and understanding Overall, the 3-month duration with 36 classes provides a balanced and effective learning experience that prepares students for success in the field of industrial automation.