HMI Training Course

The HMI (Human-Machine Interface) Training Course offered by Kushtia Industrial Automation is designed to provide participants with comprehensive knowledge and practical skills in designing, programming, and troubleshooting HMIs for industrial automation systems. This course is essential for individuals looking to enhance their proficiency in creating intuitive and efficient interfaces for controlling and monitoring industrial processes.

Course Overview:

The HMI Training Course covers a wide range of topics to equip participants with the skills necessary to develop user-friendly and effective HMIs. The course curriculum includes:

Introduction to HMIs: Participants will gain an understanding of the role of HMIs in industrial automation systems and their importance in facilitating human interaction with machines and processes

HMI Software Overview: This module provides an overview of popular HMI software platforms used in the industry, such as Siemens WinCC, Rockwell FactoryTalk View, and Wonderware InTouch. Participants will learn how to navigate the software interface and perform basic tasks

HMI Design Principles: Participants will learn best practices for designing intuitive and user-friendly HMIs, including layout design, color schemes, navigation menus, and alarm management. Emphasis is placed on optimizing HMI usability and efficiency.

HMI Programming Techniques: This module covers advanced HMI programming techniques, including creating dynamic graphics, animations, and data visualization. Participants will learn how to integrate multimedia elements and interactive controls to enhance user experience.

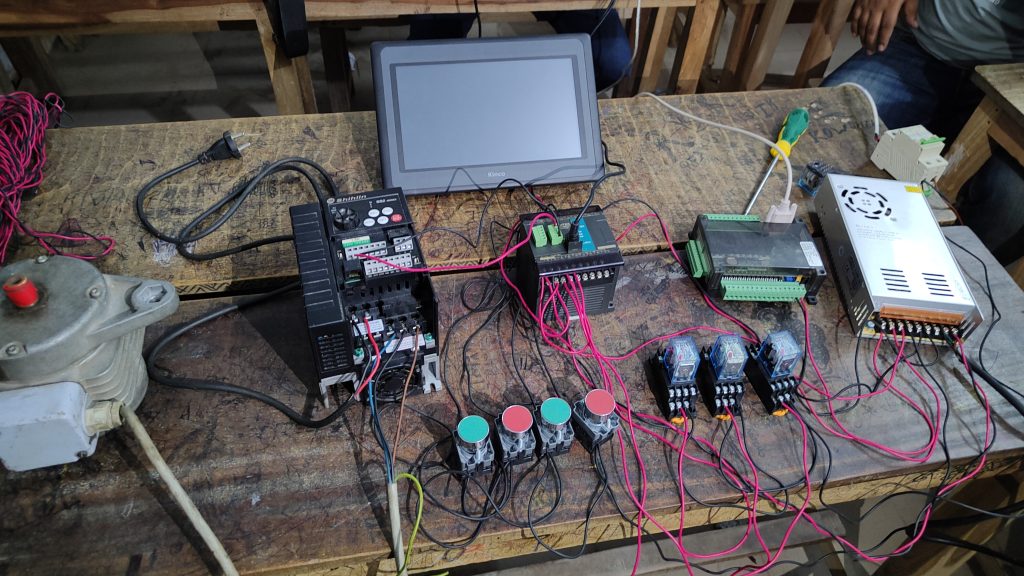

Data Acquisition and Tag Mapping: Participants will learn how to interface HMIs with PLCs and other control devices to acquire real-time data from industrial processes. Topics include tag mapping, data exchange protocols, and data logging.

Alarm Management and Notification: Participants will learn how to implement alarm management systems in HMIs to detect and respond to abnormal conditions in industrial processes. Topics include alarm prioritization, acknowledgement, and

notification

HMI Troubleshooting and Diagnostics: Participants will develop troubleshooting skills to identify and resolve common HMI-related issues. Topics include diagnosing communication errors, addressing screen freezing, and troubleshooting

hardware faults

Course Format:

The HMI Training Course combines theoretical lectures with hands-on practical exercises using industry-standard HMI software and hardware platforms. Participants will have the opportunity to design, program, and test HMIs in simulated industrial environments

Who Should Attend:

This course is suitable for engineers, technicians, and professionals involved in industrial automation, control systems, and HMI development. It is also beneficial for students and graduates seeking to pursue a career in HMI design and programming.

Prerequisites:

Participants are expected to have a basic understanding of industrial automation concepts and familiarity with PLCs and control systems. Prior experience with HMI software platforms is recommended but not required.

Certification:

If the course duration is 3 months with a total of 36 classes, it suggests that classes would be held regularly, likely on a weekly basis, with each class lasting approximately 2 to 3 hours

This setup allows for comprehensive coverage of course materials and concepts over the span of three months, ensuring that students have ample time to absorb information, participate in practical exercises, and engage with instructors.

During this period, students can expect a structured curriculum that progresses logically from foundational concepts to more advanced topics, with opportunities for hands-on practice and reinforcement of learning objectives. Additionally, assignments, projects, or assessments may be integrated throughout the course to evaluate student progress and understanding.

Overall, the 3-month duration with 36 classes provides a balanced and effective learning experience that prepares students for success in the field of industrial automation.